▲Fig. 2 XPS spectra for Zn2p3/2 (a) and S2p (b) in fresh TC; Zn L3 edge XANES analyses of fresh and spent tyre char (c); XPS spectra for Zn2p3/2 (d) and S2p (e) spectra in spent TC; and Zn L3 edge XANES analyses of ZnSO4, ZnS and ZnO standards (f).

▲Fig. 3 TEM patterns of the spent TC (a); nano-sized ZnO crystal distribution in spent TC (b); high-magnification TEM for single ZnO particle in (c) and (d); and SEAD pattern of ZnO in (e).

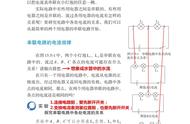

酸性位分析

众所周知,生物质挥发物的脱氧是酸催化过程,它取决于固体催化剂表面上存在的酸位的数量和类型。分析表明轮胎半焦中总的酸性位为296μmol/g,Bronsted/Lewis 为0.2(表2)。对于AW-TC/ZnS(oxy),由于在~675°C温度下酸性位显着增多,可以将其归因于马弗炉中ZnO硫化过程中产生的ZnSO4。改性的AW-TC/ZnS(oxy)具有最大的酸性位点(923.2μmol/ g),这与其最强的活性相呼应。

▲Table 2 Catalyst acidity and Bronsted/Lewis (B/L) acid ratios

催化剂表面反应机理

研究表明轮胎半焦表面不同的酸性位具有很强的协同作用。含氧生物挥发分在轮胎半焦表面的吸附促使表面ZnS原位硫酸化为ZnSO4, 从而使其由Lewis酸转为较强的Bronsted酸。此外催化剂表面上的有机S和ZnS之间的协同作用使得活性较低的ZnO原位硫化为ZnS,从而使生物质挥发分连续暴露于高活性的ZnS及其衍生物ZnSOx中。

▲Fig. 4 Specified catalytic mechanism of Zn-S bearing species for an in-situ formation of ZnSO4-centered super acid in scrap TC. Step 1 refers to the adsorption of C-O bonds on Lewis acid site; Step 2 is for the stabilisation of the fragmented organic moieties by proton from Brønsted acid on the catalyst surface; Step 3 stands for the deoxygenation of bio-oil for the formation of gaseous CO and CO2; Step 4 refers to the adsorption of protons (from water or bio-oil vapour) with unpaired Zn and S on the surface for an in-situ formation of local super strong acid; and Step 5 is for the in-situ sulphidation of Zn2 for the regeneration of ZnS-centered acidic site.

产物表征

生物油通过气相色谱-质谱仪(GC-MS)分析。如图5所示,当增加轮胎半焦对生物质的质量比时,生物油的颜色变得更浅且保留时间范围明显缩小。其定量结果表明在仅生物质的情况下,D-阿洛糖(C6H12O6)占53%,但是,在使用等量轮胎半焦时减半。当增加催化剂的质量比到4:1时,D-阿洛糖进一步减至仅2.6%。相反,糠醛(C5H4O2)的收率从4.3%增至42.0%(轮胎半焦/生物质为4:1)。就大多数酚类芳族化合物而言,其收率变化很小,这意味着轮胎半焦催化剂对酚类芳香族化合物的脱氧作用较差。此外,AW-TC/ZnS(oxy)的GC-MS结果表明与生物质等质量比使用AW-TC/ZnS(oxy)可以显着提高糠醛的收率,甚至高于原始TC。一旦质量比增加到4:1,这两种催化剂之间的差异也可以忽略不计,该结果进一步表明硫酸锌对于从生物质中高糠醛选择性的必要性。