第一篇编程说明

目录

第一章编程基础......................................................................................................Ⅰ-1

1.1 GSK980TD简介..........................................................................................Ⅰ-

1

1.2 机床数控系统和数控机床.............................................................................Ⅰ-6

1.3 编程基本知识..............................................................................................Ⅰ-8

1.3.1 坐标轴定义.........................................................................................Ⅰ-8

1.3.2 机床坐标系和机械零点.......................................................................Ⅰ-9

1.3.3 工件坐标系和程序零点.......................................................................Ⅰ-9

1.3.4 插补功能............................................................................................Ⅰ-9

1.3.5 绝对坐标编程和相对坐标编程..........................................................Ⅰ-10

1.3.6 直径编程和半径编程........................................................................Ⅰ-11

1.4 程序的构成................................................................................................Ⅰ-12

1.4.1 程序的一般结构................................................................................Ⅰ-13

1.4.2 主程序和子程序................................................................................Ⅰ-16

1.5 程序的运行................................................................................................Ⅰ-17

1.5.1 程序运行的顺序................................................................................Ⅰ-17

1.5.2 程序段内指令字的执行顺序..............................................................Ⅰ-18 第二章 MSTF 指令...................................................................................................Ⅱ-1

2.1 M 指令(辅助功能)...................................................................................Ⅱ-1

2.1.1 程序结束M02 ....................................................................................Ⅱ-1

2.1.2 程序运行结束M30 .............................................................................Ⅱ-1

2.1.3 子程序调用M98.................................................................................Ⅱ-2

2.1.4 从子程序返回M99 .............................................................................Ⅱ-2

2.1.5 宏程序调用M9000~M9999 ..............................................................Ⅱ-3

2.1.6 标准PLC 梯形图定义的M 指令.........................................................Ⅱ-

3

2.1.7 程序停止M00 ....................................................................................Ⅱ-3

2.1.8 主轴正转、反转停止控制 M03、M04、M05......................................Ⅱ-4

2.1.9 冷却液控制M08、M09 ......................................................................Ⅱ-4

2.1.10 尾座控制M10、M11 ........................................................................Ⅱ-4

2.1.11 卡盘控制M12、M13 ........................................................................Ⅱ-4

2.1.12 润滑液控制M32、M33 ....................................................................Ⅱ-4

2.1.13 主轴自动换档M41、M42、M43、M44............................................Ⅱ-4

2.2 主轴功能......................................................................................................Ⅱ-5

2.2.1 主轴转速开关量控制..........................................................................Ⅱ-5

2.2.2 主轴转速模拟电压控制.......................................................................Ⅱ-5

2.2.3 恒线速控制G96、恒转速控制G97....................................................Ⅱ-6 第一

篇编程说明

2.3 刀具功能......................................................................................................Ⅱ-9 2.4 进给功能....................................................................................................Ⅱ-12

2.4.1 切削进给(G98/G99、F 指令).......................................................Ⅱ-12

2.4.2 螺纹切削 ..........................................................................................Ⅱ-14

2.4.3 手动进给 ..........................................................................................Ⅱ-14

I

2.4.4 手轮/单步进给 ..................................................................................Ⅱ-15

2.4.5 自动加减速.......................................................................................Ⅱ-15

第三章 G 指令..........................................................................................................Ⅲ-1

3.1 概述.............................................................................................................Ⅲ-1

3.1.1 模态、非模态及初态...........................................................................Ⅲ-2

3.1.2 指令字的省略输入 ..............................................................................Ⅲ-2

3.1.3 相关定义.............................................................................................Ⅲ-3

3.2 快速定位 G00..............................................................................................Ⅲ-4 3.3

直线插补 G01..............................................................................................Ⅲ-5

3.4 圆弧插补 G02、G03....................................................................................Ⅲ-6

3.5 暂停指令 G0

4..............................................................................................Ⅲ-9

3.6 返回机械零点 G28.....................................................................................Ⅲ-10

3.7 工件坐标系设定 G50 .................................................................................Ⅲ-11

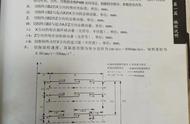

3.8 固定循环指令.............................................................................................Ⅲ-12

3.8.1 轴向切削循环 G90............................................................................Ⅲ-12 3.8.2

径向切削循环 G94............................................................................Ⅲ-14

3.8.3 固定循环指令的注意事项..................................................................Ⅲ-17

3.9 多重循环指令.............................................................................................Ⅲ-18

3.9.1 轴向粗车循环 G71............................................................................Ⅲ-18

3.9.2 径向粗车循环 G72............................................................................Ⅲ-21 3.9.3

封闭切削循环 G73............................................................................Ⅲ-25

3.9.4 精加工循环 G70 ...............................................................................Ⅲ-29 第一篇 GSK980TD 车床 CNC

3.9.5 轴向切槽多重循环 G7

4.....................................................................Ⅲ-30 3.9.6 径向切槽多重循环 G7

5.....................................................................Ⅲ-32 3.10 螺纹功能..................................................................................................Ⅲ-35 3.10.1 等螺距螺纹切削指令 G32...............................................................Ⅲ-35 3.10.2 变螺距螺纹切削指令 G34...............................................................Ⅲ-37 3.10.3 Z 轴攻丝循环 G33 ..........................................................................Ⅲ-39 3.10.4 螺纹切削循环 G92..........................................................................Ⅲ-40 3.10.5 多重螺纹切削循环 G7

6...................................................................Ⅲ-43 3.11 恒线速控制 G96、恒转速控制 G9

7..........................................................Ⅲ-47 3.12 每分钟进给 G98、每转进给 G99.............................................................Ⅲ-49 3.13 宏指令 .....................................................................................................Ⅲ-50 3.13.1 宏变量............................................................................................Ⅲ-50 3.13.2 运算命令和转移命令 G65...............................................................Ⅲ-51 3.13.3 宏指令编程示例..............................................................................Ⅲ-55 第四章 刀尖半径补偿(G41、G42)............................................................................Ⅳ-1

4.1 刀尖半径补偿的应用..........................................................................................Ⅳ-1

4.1.1 概述..........................................................................................................Ⅳ-1 4.1.2 假想刀尖方向............................................................................................Ⅳ-1 4.1.3

补偿值的设置............................................................................................Ⅳ-5

4.1.4 指令格式...................................................................................................Ⅳ-6

4.1.5 补偿方向...................................................................................................Ⅳ-6

4.1.6 注意事项...................................................................................................Ⅳ-7

II

目 录

4.1.7 应用示例...................................................................................................Ⅳ-8

4.2 刀尖半径补偿偏移轨迹说明 ...............................................................................Ⅳ-9

4.2.1 内侧、外侧概念........................................................................................Ⅳ-9

4.2.2 起刀时的刀具移动 ....................................................................................Ⅳ-9

4.2.3 偏置方式中的刀具移动...........................................................................Ⅳ-11

4.2.4 偏置取消方式中的刀具移动....................................................................Ⅳ-16

4.2.5 刀具干涉检查 .........................................................................................Ⅳ-17

4.2.6 暂时取消补偿向量的指令........................................................................Ⅳ-19

4.2.7 特殊情况.................................................................................................Ⅳ-20

编程说明

第一篇编程说明

第一章 编程基础

Ⅰ-1 第一章 编程基础

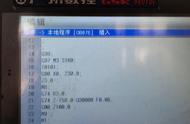

1.1 GSK980TD 简介 广州数控研制的新一代普及型车床CNC GSK980TD 是GSK980TA 的升级产品,采用了32位高性能CPU 和超大规模可编程器件FPGA ,运用实时多任务控制技术和硬件插补技术,实现μm 级精度运动控制和PLC 逻辑控制。 产品技术特点:

X 、Z 二轴联动、μm 级插补精度, 高速度16米/分(可选配30米/分)

内置式PLC ,可实现各种自动刀架、主轴自动换档等控制,梯形图可编辑、上传、下载;I/O 口可扩 展(选配功能)

具有螺距误差补偿、反向间隙补偿、刀具长度补偿、刀尖半径补偿功能 采用S 型、指数型加减速控制,适应高速、高精加工

具有攻丝功能,可车削公英制单头/多头直螺纹、锥螺纹、端面螺纹,变螺距螺纹,螺纹退尾长度、 角度和速度特性可设定,高速退尾处理 集成中文、英文显示界面,由参数选择

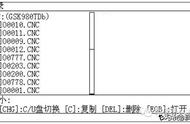

零件程序全屏幕编辑,可存储6144KB 、384个零件程序 提供多级操作密码功能,方便设备管理

支持CNC 与PC 、CNC 与CNC 间双向通讯,CNC 软件、PLC 程序可通讯升级 安装尺寸、电气接口、指令系统、操作显示界面与980TA 兼容

第一篇编程说明